The Real Purpose of Those Mysterious Lines on Towels

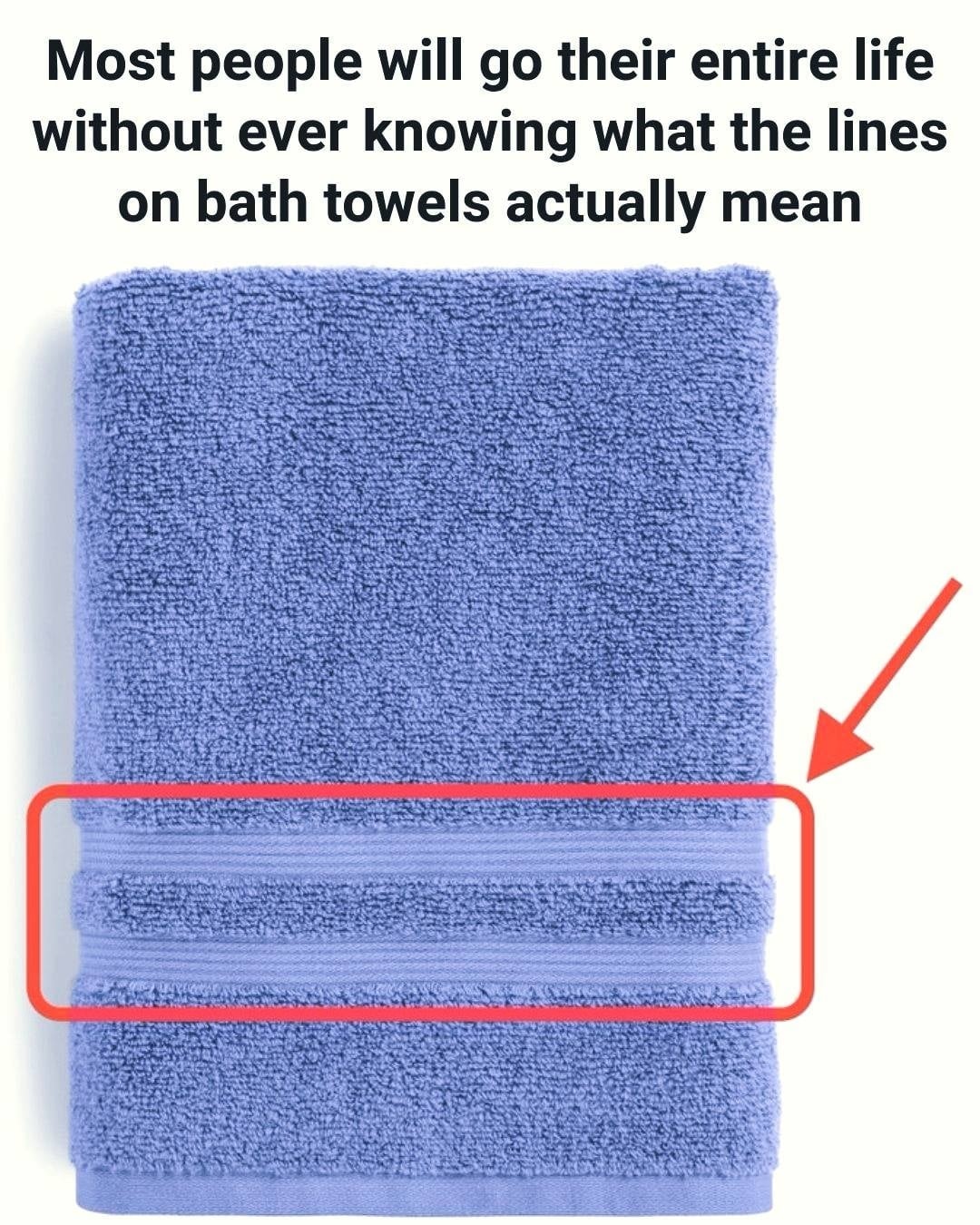

Take a closer look at the towels in your bathroom or kitchen. Near each end, you’ll often notice a set of woven lines or a slightly different band of fabric running across the width. Most people never think twice about it—or assume it’s purely decorative. But those lines are there for very practical reasons, tied to how towels are made, how they perform, and how long they last.

What looks like a simple design detail is actually the result of thoughtful textile engineering.

What are those lines called?

The woven band you see near the ends of many towels is commonly known as a dobby border. Unlike the fluffy terry loops that make up most of the towel’s surface, this section is tightly woven and flatter.

Its different texture is intentional. Towels aren’t just pieces of cloth; they’re products designed to withstand repeated use, washing, pulling, and drying without falling apart or losing their shape.

Reinforcing the most stressed areas

One of the main purposes of the dobby border is structural reinforcement.

Think about how you use a towel:

-

You grab it by the ends

-

You hang it over bars or hooks

-

You fold it repeatedly

-

You tug on it when drying off

All of this stress concentrates near the edges. If the entire towel were made only of looped terry fabric, those loops could stretch, distort, or fray more easily over time.

The tightly woven border acts like a stabilizing frame. It strengthens the towel where wear and tear are most likely to occur, helping prevent unraveling and extending the towel’s usable life.

Helping the towel keep its shape

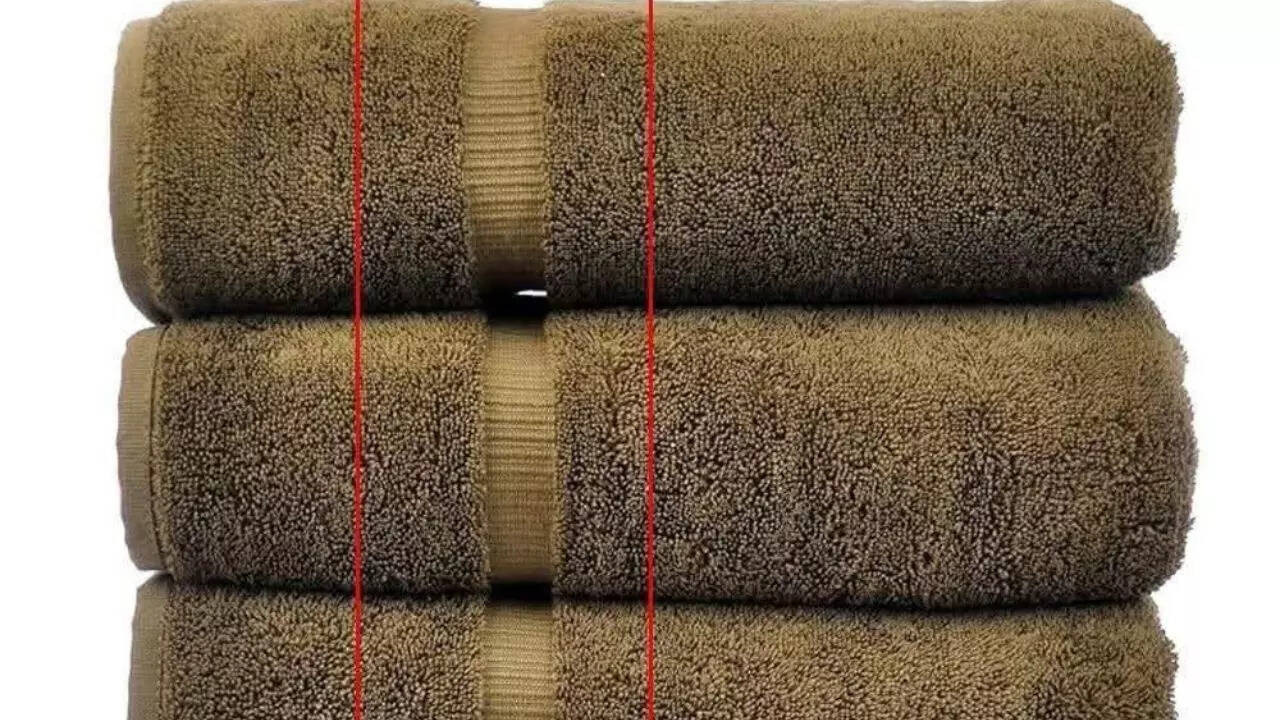

Towels go through a lot in the laundry: hot water, spinning cycles, detergents, and heat from dryers. Over time, fabrics can stretch unevenly if they lack structure.

The dobby border helps maintain shape consistency. By anchoring the towel’s ends, it reduces warping and curling, which keeps the towel lying flat and folding neatly even after dozens of washes.

Without this stabilizing band, towels would be more likely to become misshapen, making them less comfortable to use and less visually appealing.

Preserving absorbency where it matters most

At first glance, you might think adding a non-terry section would reduce absorbency. In reality, it does the opposite—indirectly.

The main drying power of a towel comes from the terry loops in the center. If the towel stretches or deforms, those loops don’t function as efficiently. By reinforcing the ends, the dobby border helps the towel’s core area stay plush and properly aligned, preserving overall absorbency.

In short: the border doesn’t absorb much water itself, but it helps the rest of the towel do its job better.

A key role in manufacturing and quality control

The lines on towels also serve an important function behind the scenes, during production.

In large-scale towel manufacturing, consistency is critical. The dobby border acts as:

-

A visual guide for cutting and sizing

-

A structural marker for folding and stitching

-

A reference point for inspection and quality checks

Because the border is woven differently, machines and workers can easily ensure towels are uniform before packaging. This improves efficiency and reduces defects.

For branded towels, the border also provides a clean, stable area to place logos or decorative patterns without interfering with absorbent sections.

A subtle signal of quality

Beyond function, there’s also an aesthetic and psychological element.

The presence of a well-defined border gives towels a finished, intentional look. It visually separates a towel from basic cloth or improvised fabric, signaling that it’s a purpose-built household item.

Many consumers subconsciously associate these lines with durability, craftsmanship, and hotel-quality textiles. That perception isn’t accidental—it reflects real design choices made to balance appearance and performance.

Why not make the whole towel like that?

If the dobby border is so useful, why isn’t the entire towel made from the same weave?

Because towels need two opposing qualities:

-

Softness and absorbency (from terry loops)

-

Strength and stability (from tight weaving)

Using only one type of fabric would compromise the other. The combination allows towels to be both effective and durable—soft where you need comfort, firm where you need support.

A small detail with a big purpose

Those “mysterious” lines on towels aren’t decorative leftovers or random design flourishes. They’re a practical solution refined over decades of textile production.

They:

-

Reinforce high-stress areas

-

Help towels keep their shape

-

Protect long-term absorbency

-

Improve manufacturing consistency

-

Add a clean, polished appearance

It’s a reminder that even everyday objects are often more thoughtfully designed than they appear. Sometimes, the smallest details are doing the most work—quietly making sure the things we rely on every day last longer and perform better.

Next time you dry your hands or step out of the shower, you’ll know: those lines are there for a reason.